The University of Tennessee Research Foundation is proud to partner with Dustin Crouch, 2025 Chancellors Innovation Award finalist and Associate Professor in the Department of Mechanical, Aerospace, and Biomedical Engineering at the University of Tennessee.

Crouch’s work in prosthetics pushes the boundaries of biomedical engineering to improve quality of life for people who have experienced amputation, starting with the thumb.

Revolutionizing Prosthetics with Implantable Devices

Crouch has been working with UTRF since his arrival to UTK. He has two patent pending applications and six disclosures, with five related to implantable prosthetic innovations.

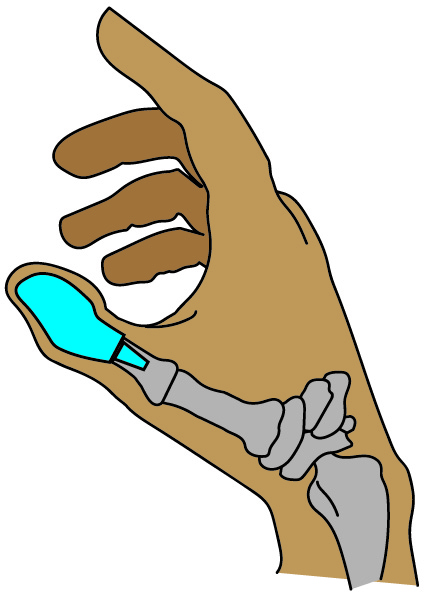

His platform technology is a new type of implantable prosthesis that is anchored into a bone, completely enclosed by skin, and connected and controlled the patient’s own muscles, mimicking the functionality of the appendage before it was lost. With over 40% of external prosthesis owners abandoning their prosthesis all together, this innovation will offer a more natural and functional alternative, and help users restore their quality of life.

The first application for this technology will be an implantable skin-covered thumb prosthesis, EndoThumb. EndoThumb will look to restore thumb movement and functionality, along with the appearance, and sensory feedback which lack in existing solutions.

The potential market for this technology is considerable. Each year, approximately 5,000 to 6,000 people in the United States suffer thumb amputations, with an estimated 2 million people globally living with thumb amputation.

To help Crouch navigate the path to commercialization, UTRF assigned Bob Vanderhoff, UTRF Executive-in-Residence, to mentor him in business development.

“It’s really been interesting to see the evolution of Dustin through this process,” Vanderhoff said. “When I first met him, he was coming at his research from more of an academic perspective. Seeing him begin to understand the commercial viability as he’s expanded his horizons and moved toward commercializing this idea has been cool.”

Once commercialized, healthcare providers can use Crouch’s implantable prosthetic technology to offer patients better outcomes.

“So much work goes into developing an implantable prosthetic technology and understanding its market potential,” said Gregory Sechrist, UTRF Technology Manager. “Dustin has put in a lot of work to better understand the various challenges of bringing a product like this to market and has done a great job of utilizing the resources around him to help him be successful. We are excited to see this technology moving forward and we hope the thumb is only the beginning.”

While Crouch’s team is currently focusing on a thumb prosthesis, Crouch has broader goals to adapt the technology for other areas of the body, including hands, fingers, toes, feet, and eventually larger appendages such as arms and legs.

Crouch’s co-inventors on this technology include David Anderson, Associate Dean for Research and Graduate Studies at the University of Tennessee College of Veterinary Medicine, and Stacey Stephenson, Plastic Surgeon and Assistant Professor at The University of Tennessee Medical Center. Through these collaborations Crouch has been able to demonstrate proof-of-concept testing and continued development.

“The studies proved the concept that we can implant a device like this at the end of a limb that has had an amputation and cover it in living skin and have that skin heal,” Crouch said. “The data so far suggests that animals were able to use it as a foot and ankle prosthesis so they could bear weight on it while they were moving around.”

Pioneering Work and Support

Crouch’s work has already garnered attention and support from both academic and industry partners.

His team has received grants from the National Institutes of Health (NIH) and the National Science Foundation (NSF) to fund studies and further development of the technology. This year, Katrina Easton was selected as a UTRF Entrepreneurial Fellow. As an Entrepreneurial Fellow, Katrina will assist Dustin with developing a minimum viable product of the EndoThumb implant, pushing the innovation towards commercialization.

“I’m really excited,” Crouch said. “There’s so much momentum, it seems, in the last six months, especially with a senior design team working on it and the investments from UTRF and the University. I think the next year will be critical for moving this towards a viable product.”