Thermoelectric-Base Heat Exchanging Technology for Fluid Foods and Beverage Pasteurization (TESS)

The Problem

The most prevalent method for perishable beverage pasteurization currently is High-Temperature Short-Time Pasteurization (HTST) which typically results in a 5-log reduction of harmful bacteria. This method, while effective, requires a high degree of complexity of water feed lines, valves, pumps, and lots of natural gas for heating. Conversion of natural gas to heat involves inherent energy loss and use of natural gas contributes to greenhouse gas emissions problems.

The Solution

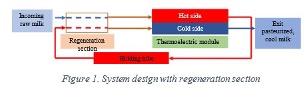

Researchers at the University of Tennessee have developed a Pasteurization System which reduces energy use over HTST systems by removing hot/cold water lines, as well as greatly simplifying pasteurization equipment from a pumping/valves perspective resulting in lowered maintenance costs. The system utilizes a thermoelectric heating in order to reduce system complexity, energy use, and resulting greenhouse gas emissions.

Benefits

| Benefit |

|---|

| Utilization of the TESS system in place of traditional HTST processes is estimated to reduce CO2-equivalent emissions by about 1.1 million metric tons per year in fluid milk-pasteurization alone. |

| Estimated 20% energy efficiency improvement over HTST processes. |

| Greatly simplifies pasteurization equipment from pumping/valves perspective and reduces maintenance costs and facility space required. |

More Information

- Tyler Newton

- Assistant Technology Manager

- 865-974-1882 | cnewto12@tennessee.edu

- UTRF Reference ID: 24008

- Patent Status: Patent Pending

Innovators

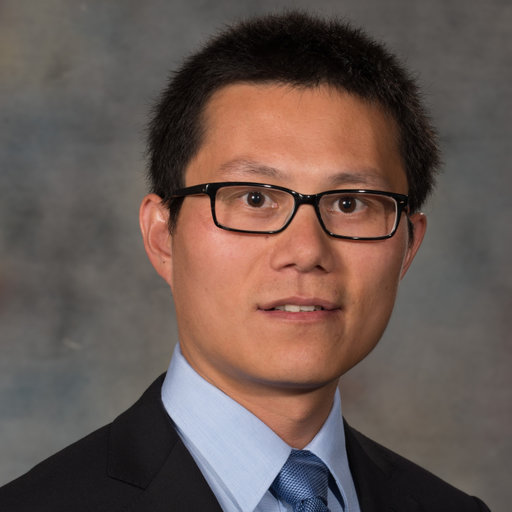

Jiajia Chen

Professor, Department of Food Science, UTIA, UT Knoxville

Dr. Chen received his Ph.D. in Agricultural and Biological Systems Engineering from the University of Nebraska-Lincoln in 2015. Dr. Chen’s current food engineering research program mainly focuses on developing multiphysics and multi-scale modeling of food processes for improving food quality and safety. Dr. Chen’s research program helps the food industry in developing and adopting novel and improved food processing technologies to manufacture nutritious, high-quality, and safe food products.

Read more about Jiajia ChenMark Morgan

Professor, Department of Food Science, UTIA, UT Knoxville

Dr. Morgan received his Ph.D. in Agricultural Engineering from Ohio State University in 1991. His research interests include sterilization technologies and process engineering and intervention technologies for improving food quality.

Read more about Mark Morgan