Flexible Printed Circuit Board Bonding Power Module with Wide Temperature Range

The Problem

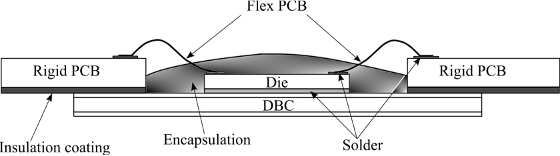

The design of most power modules involves mounting semiconductor die to direct bonded copper (DBC). However, differences in coefficients of thermal expansion between DBC, PCB, die, and encapsulation elements often leads to damage in thermal cycling. Conventional wire-bonding and pure flex PCB packaging methods often result in high costs, difficult manufacturing methods, and failure to solve the issue of thermal stress reduction in wide temperature range applications like cryogenics.

The Solution

Researchers at the University of Tennessee have developed a Power Module package which utilizes a unique geometry of both rigid and flexible PCB (FPCB) to achieve high thermal stress reduction across a wide temperature range, as well as provide low-parasitics connection to the semiconductor die. The lack of wire bonding improves reliability, while the substitution of some FPCB for rigid PCB reduces cost significantly.

Benefits

| Benefit |

|---|

| Use of both rigid and flexible PCB optimizes cost with ability to withstand mechanical stresses of thermal expansion. |

| Provides low inductance and low resistance connection to the semiconductor die. |

| The manufacturing method is simple and cost-effective, and the geometry allows for the void between PCB and die to be easily filled with encapsulant. |

| Utilizes encapsulation material which provides good insulation for the power module through cryogenic temperatures. |

More Information

- Gregory Sechrist

- Technology Manager

- 865-974-1882 | gsechris@tennessee.edu

- UTRF Reference ID: 23076

- Patent Status: Patent Pending

Innovators

Dr. Fei "Fred" Wang

Professor and Condra Chair of Excellence in Power Electronics, Min H. Kao Department of Electrical Engineering and Computer Science, UT Knoxville

Dr. Wang received his Ph.D. in Electrical Engineering from the University of Southern California in 1990. His research interests include Power Electronics, Power Systems, and Motor Drives.

Read more about Dr. Fei "Fred" WangDr. Hua "Kevin" Bai

Associate Professor, Min H. Kao Department of Electrical Engineering and Computer Science, UT Knoxville

Dr. Bai received his PhD in Electrical Engineering from Tsinghua University in Beijing, China in 2007. His research interests include EV related battery chargers, motor drive systems, and applications of wide-bandgap devices.

Read more about Dr. Hua "Kevin" Bai