SMART JOINT Integrated Monitoring of Adhesive Joints and Additive Materials

The Problem

Adhesive bonded joints join similar/dissimilar materials without machining or damaging the materials enabling greater flexibility and efficiency in manufacturing. The joint is also heavily dependent on the quality of the manufacturing process. The joints also present a complex pattern of failure modes which is impossible to predict and challenging to study with traditional testing. New testing methods will enable engineers to deliver these new solutions.

The Solution

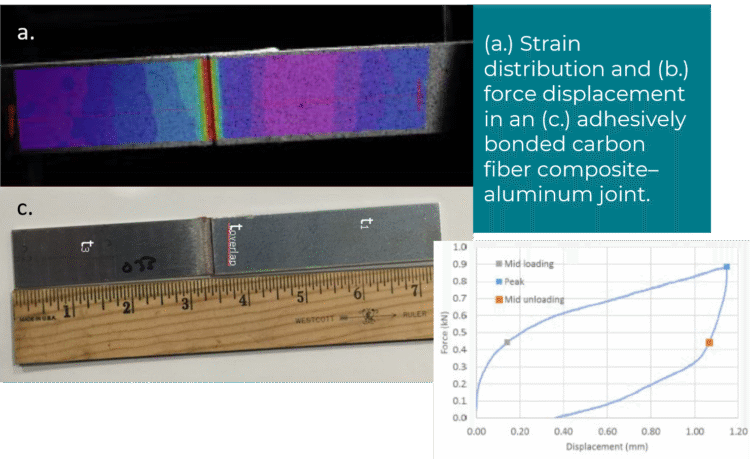

Researchers at the University of Tennessee have developed an innovative “Smart Joint” sensor that can provide real-time stress/strain values. The fiber optic sensor is integrated with the joint to assess failures in real-time and with spatial information (a, b). With this information engineers can find optimal configurations and manufacturing processes to achieve their goals. In our example (c), researchers bonded a carbon fiber composite and aluminum with a methacrylate-based adhesive. The “Smart Joint” functions with the joining of any materials such as: concrete, metals, glass or carbon composites.

Benefits

| Benefit |

|---|

| Sensor is integrated during or after formation of adhesive joint |

| Measures strain and corresponding stress tensor |

| Data can be collected periodically or continuously |

| Can be used between two similar or dissimilar materials |

More Information

- Derek Eitzmann

- Assistant Technology Manager

- 865-974-1882 | deitzman@tennessee.edu

- UTRF Reference ID: 17023-03

- Patent Status: US20190193338A1

Innovators

Dayakar Penumadu

Fred N. Peebles Professor in Department of Civil and Environmental Engineering

Dr. Penumadu is a professor and the IAMM Chair of Excellence at UT. He received his Ph.D. from the Georgia Institute of Technology, and his research interests include carbon fiber reinforced polymeric composites and sandwich structures, environmental degradation, and multi-scale mechanics; multi-axial stress-strain-time behavior of multi-phase and granular materials; and non-invasive characterization and residual stress using neutron and x-ray tomography and diffraction. He is currently a Principal Investigator for a NSF IUCRC on Hybrid Composite Material Joining.

Read more about Dayakar Penumadu