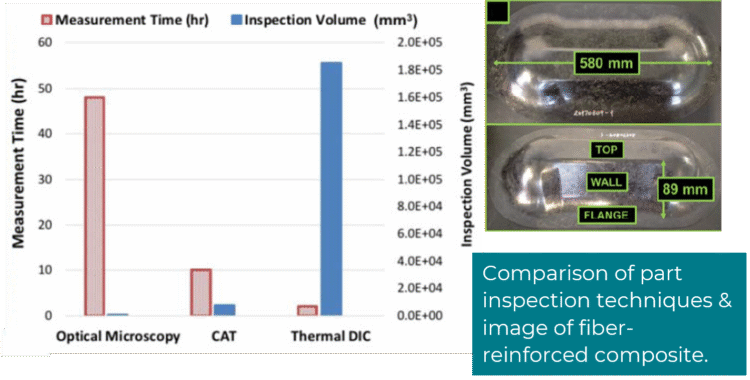

Fiber Impregnated Composite Analysis by Thermal Digitial Image Correlation TDIC

The Problem

Continuous and discontinuous fiber reinforced composites, such as sheet molding composites (SMCs) can provide enhanced strength and weight-reduction compared to typical materials like aluminum. The disadvantage of this processing technique is that the mechanical performance can vary due to the dispersion of fibers within the composite. Commonly, destructive testing is performed to determine part quality which is costly, time consuming, and does not provide spatial resolution.

The Solution

Researchers at the University of Tennessee have developed a novel method of analysis for a variety of pre-impregnated composite parts and materials using Thermal Digital Image Correlation (TDIC). This TDIC method is capable of rapidly determining spatial variations in fiber orientation, detection of matrix rich regions, and the resulting mechanical properties both pre- and post-thermal molding in parts. Analysis can be conducted on a wide variety of materials to predict properties such as thermal conductivity, diffusivity, specific heat, stiffness, and strength. The method is suitable for large- or small- scale specimens for rapid prototyping or quality assurance.

Benefits

| Benefit |

|---|

| Non-destructive enabling orthogonal pre/post analysis |

| Compatible with ceramic, polymer, and metal-based matrixes |

| Repair, patching, or hybrid joint analysis |

| Fatigue, static & dynamic strength, thermal resistance, and crash worthiness trait determination. |

More Information

- Derek Eitzmann

- Assistant Technology Manager

- 865-974-1882 | deitzman@tennessee.edu

- UTRF Reference ID: 18162

- Patent Status: US11435486B2

Innovators

Dayakar Penumadu

Fred N. Peebles Professor in Department of Civil and Environmental Engineering

Dr. Penumadu is a professor and the IAMM Chair of Excellence at UT. He received his Ph.D. from the Georgia Institute of Technology, and his research interests include carbon fiber reinforced polymeric composites and sandwich structures, environmental degradation, and multi-scale mechanics; multi-axial stress-strain-time behavior of multi-phase and granular materials; and non-invasive characterization and residual stress using neutron and x-ray tomography and diffraction. He is currently a Principal Investigator for a NSF IUCRC on Hybrid Composite Material Joining.

Read more about Dayakar Penumadu