Large Component Non-Destructive Inspection Method

The Problem

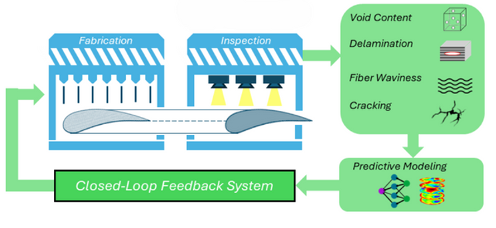

Nondestructive inspection (NDI) is a vital tool for industries to support defect detection, material characterization, and overall processing quality control. Existing NDI technologies are costly, provide slow inspection and analysis, and are not applicable to all types of manufactured components.

The Solution

Researchers from the University of Tennessee have developed a vision inspection system for applications in NDI. This system identifies material properties, such as composite fiber directionality, thermomechanical response, and residual stress. This technique also identifies various defects, including microcracking, delamination, and kissing bond defects. This process causes no damage to the components and has an improved measurement speed from other NDI processes.

Benefits

| Benefit |

|---|

| Cost-effective inspection that improves efficiency of NDI processes |

| Able to be directly integrated into existing manufacturing lines |

| Compatible with large components |

| Applicability in a wide range of industries and applications, including aerospace, wind turbines, composites, defense, and transportation |

More Information

- UTRF Reference ID: 22078

- Patent Status: WO2023192585A1

Innovators

Ryan Spencer

Dr. Spencer received his Ph.D. from the University of Tennessee in 2023. His research interests include polymer composite manufacturing and characterization, polymer additive manufacturing, and nondestructive component evaluation techniques.

Dr. Spencer is currently a staff scientist at Oak Ridge National Laboratory.

Read more about Ryan SpencerUday Vaidya

UT/ORNL Governor's Chair in Advanced Composites Manufacturing Professor; Mechanical, Aerospace and Biomedical Engineering (MABE) Chief Technology Officer; Institute for Advanced Composites and Manufacturing Innovation (IACMI)

Dr. Vaidya received his Ph.D. in Mechanical and Materials Engineering from Auburn University in 7993 and joined UT in 2075. Previously, he earned his B. S. in Mechanical Engineering at Karnataka University, India, and his M.S. in Mechanical Design Engineering at Shivaji University, India. His research focuses on advanced composites manufacturing, composite materials applications, nano-bio materials, and composites recycling/ sustainability.

Read more about Uday Vaidya