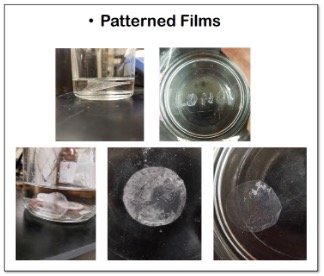

Printing & Patterning with Polyolefins

The Problem

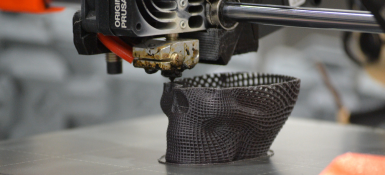

Due to their remarkable thermal and mechanical properties, polyolefins are the most widely produced and used polymers in the world. Despite their highly desirable properties, polyolefins are not amenable to standard methods of 3-D printing, which has rapidly become a primary tool to produce advanced device architectures and designer parts.

The Solution

Researchers at the University of Tennessee have developed new chemistries that facilitate the 3-D printing of polyolefins using a gas phase, polyolefin polymerization process. This method is enabled via photo-activated olefin polymerization catalysts, and provides the ability to grow, print, and pattern conformal polyolefin films.

Benefits

| Benefit |

|---|

| Limited materials |

| No messy liquid feedback |

| Readily available, low-cost monomer |

More Information

- Derek Eitzmann

- Assistant Technology Manager

- 865-974-1882 | deitzman@tennessee.edu

- UTRF Reference ID: 18037

- Patent Status: US11987653B1

Innovators

Dr. Brian Long

Professor, Department of Chemistry, UT Knoxville

Dr. Long received his PhD from the University of Texas at Austin in 2009. He also completed a postdoc at Cornell University from 2009-2011. His research interests include the design and synthesis of functional polymeric materials, and the development and utilization of next-generation polymerization catalysts.

Read more about Dr. Brian LongDr. Jordan Kaiser

Leather Technology Manager, Rawlings Sporting Goods

Dr. Kaiser received his PhD from the University of Tennessee Knoxville in 2019. His position involves managing the production process of MLB leather, building an R&D lab on-site with instrumentation acquisition and proper SOP development, improving QC protocols and testing methods, and developing new leathers requested by customers, exploring alternative raw material and interacting directly with suppliers.

Read more about Dr. Jordan Kaiser