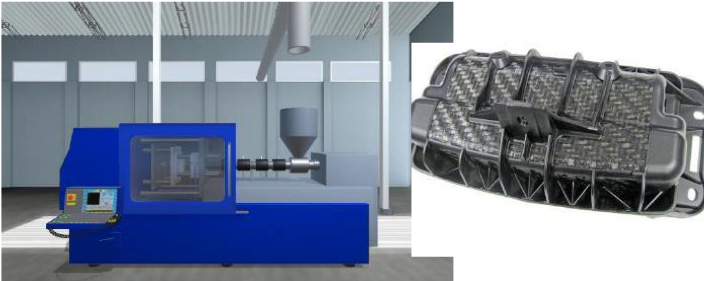

VR simulation of an injection molding setup including polymer and fiber injection. This module will walk the user through the fine tuning of the machine, allowing for customization of the final product through screw configuration, flight depth and clearance, fiber flow into mold cavities, etc.

Modules Overview

The University of Tennessee and IACMI-The Composites Institute have developed a series of Virtual Reality (VR) modules for Science, Technology, Engineering and Mathematics (STEM) training. This work introduces the next generation work force to the most relevant composite manufacturing technologies through unique VR immersive modular learning and comprehension. The VR modules cover state of the art composites processes used by industry.

The Composites VR Modules:

- Provide realistic training and experience in the manufacturing environment.

- Collectively address critical STEM challenges identified as a national priority through communication, talent inspiration and cultivation, and diversity emphasis using evidence-based approaches.

- Create a realistic learning environment for STEM education, customer engagement, continuous workforce training, as well as a resource to upskill or re-skill workers.

- Provide flexibility of content and modularity.

- Can be tailored for potential customization, process decisions, marketing strategy and cost savings.

Available Modules

Carbon Fiber Production

VR illustration of the flow of the carbon fiber manufacturing line and a spool of carbon fiber coming off the line.

Sheet Molding Compound (SMC)

An animated entire sequence of the SMC process & representative glass SMC compression molded automotive part.

An animated entire sequence of the SMC process & representative glass SMC compression molded automotive part.

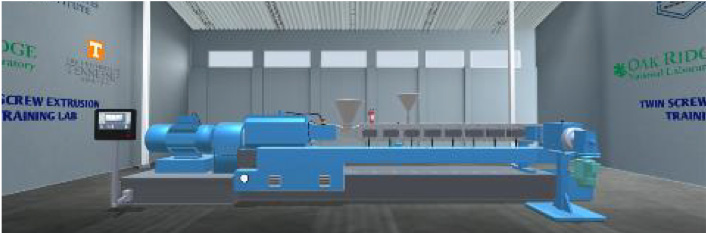

Extrusion & Twin Screw Compounding

VR illustration of the extrusion and twin screw compounding.

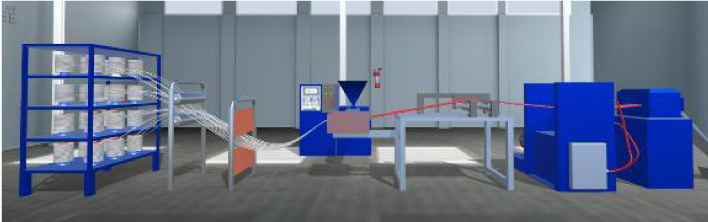

Long Fiber Thermoplastic (LFT) Production

VR illustration of hot melt impregnation of long fiber thermoplastic pellets from continuous fiber.

VR illustration of hot melt impregnation of long fiber thermoplastic pellets from continuous fiber.

Extrusion-Compression Molding (ECM)

The VR module on ECM demonstrates the use long fiber thermoplastic (LFT) pellets and its migration through the process.

Injection Molding (IM)

VR illustration of an injection molding setup including polymer and fiber injection; Injection over molded composite.

VR illustration of an injection molding setup including polymer and fiber injection; Injection over molded composite.

Pultrusion

VR on pultrusion of composites.

Roll Forming

VR on roll forming of composite profiles.

Request for Licensing Information - VR Modules

Form to request more information concerning licensing of the Virtual Reality Modules for Advanced Composites Manufacturing Technologies.