Process for In-Line Carbon Fiber Intermediates

The Problem

Carbon fiber composites are remarkable materials which provide high strength-to-weight ratio, stiffness, environmental resistance, and design flexibility. These composites are produced by integrating carbon fiber intermediates with polymer matrices and manipulated to form the desired product. The singular factor slowing wider adoption is the higher cost of fit for purpose carbon fiber intermediates.

The Solution

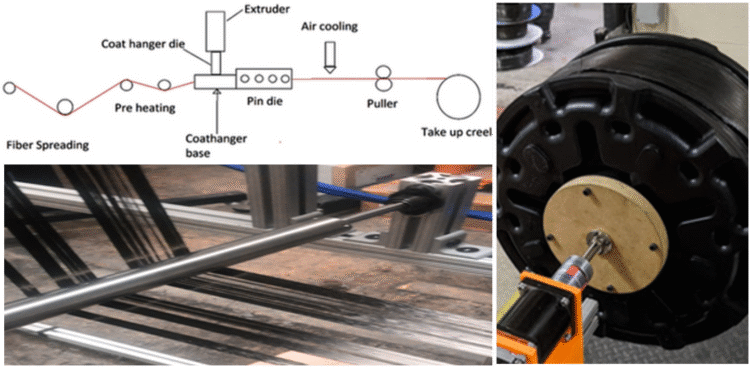

Researchers at the University of Tennessee have developed methods to reduce the costs producing carbon fiber composites. The solution features the in-line processing of raw carbon fibers into a range of intermediates for semi-finished products such as tapes, rods, pellets, etc. This process also includes the incorporation with thermoplastic or thermosetting materials to produce CFRP semi-finished products that contain carbon fiber weight fractions between 30-70%. These solutions are detailed in two patents:

Thermoplastic impregnation of large tow textile grade carbon fiber - US20250091254A1

Intermediates of 3k - 50k filaments

Process to manufacture carbon fiber intermediate products in-line with carbon fiber production - US11441001B1

Intermediates of 100k - 600k filaments

Benefits

| Benefit |

|---|

| Reduces total product costs by 35% with in-line process |

| Easily implemented into existing manufacturing lines |

| Applicable to tape placement, pulltrusion, injection molding, and compression molding. |

More Information

- Derek Eitzmann

- Assistant Technology Manager

- 865-974-1882 | deitzman@tennessee.edu

- UTRF Reference ID: 19146-03 & 20138-03

- Patent Status: US20250091254A1 & US11441001B1

Innovators

Uday Vaidya

UT/ORNL Governor's Chair in Advanced Composites Manufacturing Professor; Mechanical, Aerospace and Biomedical Engineering (MABE) Chief Technology Officer; Institute for Advanced Composites and Manufacturing Innovation (IACMI)

Dr. Vaidya received his Ph.D. in Mechanical and Materials Engineering from Auburn University in 7993 and joined UT in 2075. Previously, he earned his B. S. in Mechanical Engineering at Karnataka University, India, and his M.S. in Mechanical Design Engineering at Shivaji University, India. His research focuses on advanced composites manufacturing, composite materials applications, nano-bio materials, and composites recycling/ sustainability.

Read more about Uday VaidyaGeorge Husman

Former CTO and Director of Zoltek Corporation

Mr. George Husman began his career with the U.S. Air Force and has held senior positions at BASF, Southern Research Institute, University of Alabama Birmingham, and Zoltek. Throughout his career, his research interests have included composite materials, and manufacturing technologies and applications.

Read more about George Husman